Furniture Design. Site Practice. 2021.

Concept Development, R&D, Production.

Produced for a wealthy Mumbai business-family, the furniture collection took on a design that shouted simplicity and refinement yet showcased the raw and contrasting characteristics of the material.

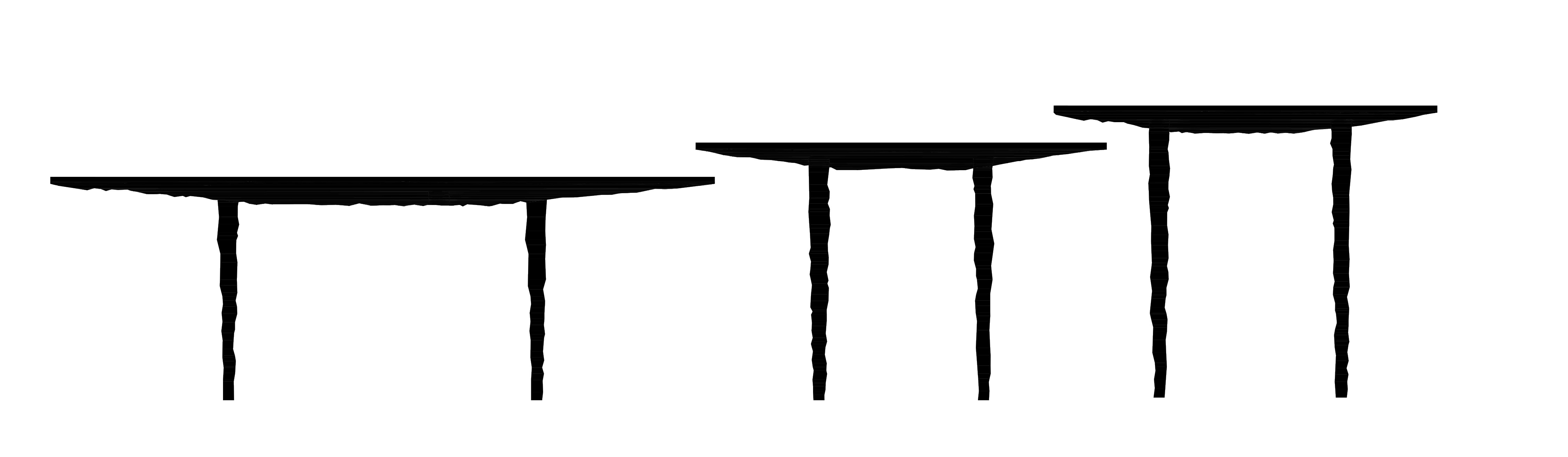

The set consists of 3 pieces: two side tables in cast brass and one in oakwood.

Working closely with the craftsmen that work with cast brass, we developed a unique method from the making of the form-work for the sand to the ultimately contrasting finishes that the table top and legs have.

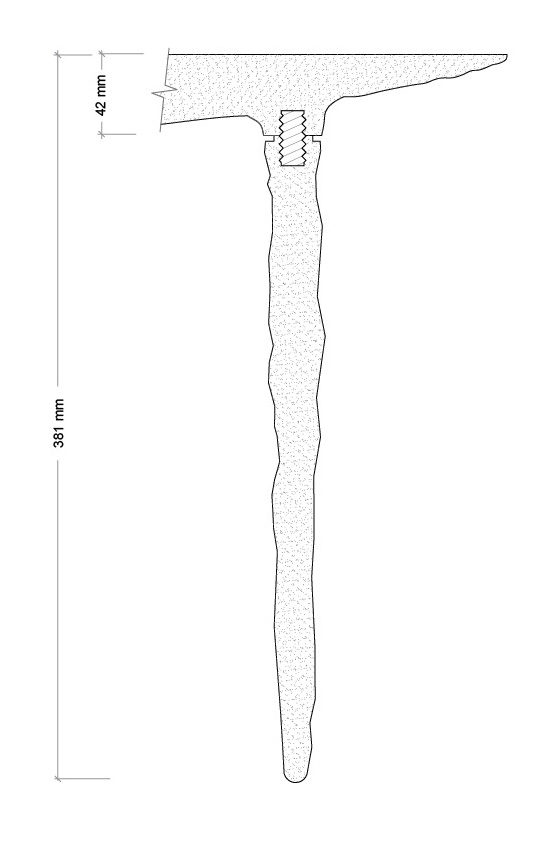

The design utilizes a single, elegant fixing detail between the cast top and the legs.

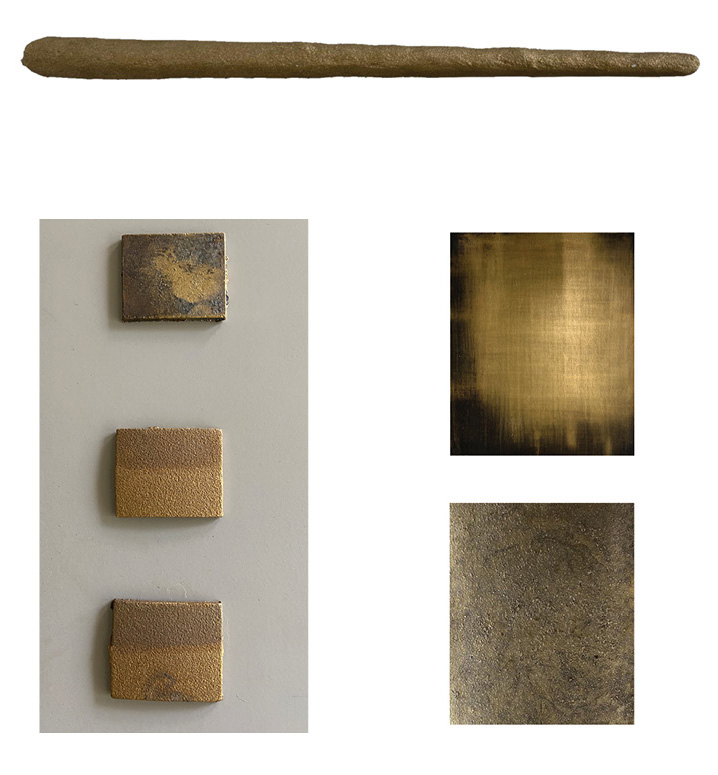

The process saw a rigorous and extensive exploration in materiality and finishes that permitted us to fine tune and perfect the final outcome with a great deal of accuracy.

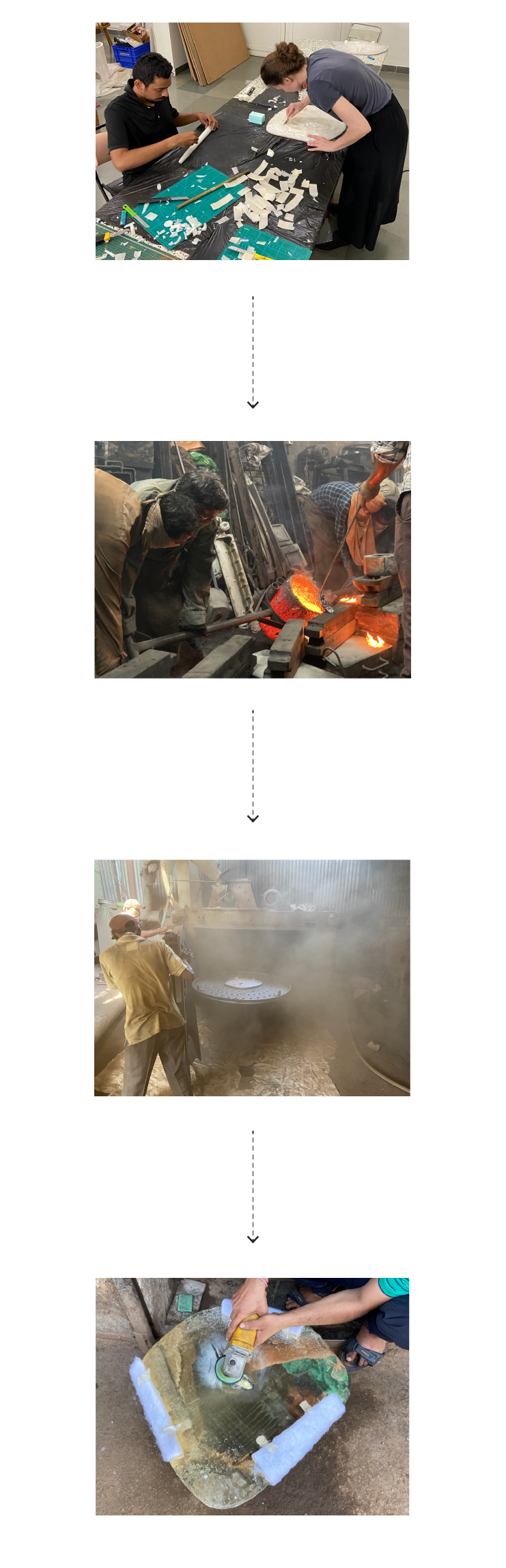

1. In order to achieve the irregular form and textured surface for the coffee and side tables, a plywood and wax form-work was made that would be used to create a mold during sand-casting.

2. The form-work was then used to create multiple moulds for sand-casting and parts that were to be duplicated.

3. The casts were then shot blasted to eliminate the inconsistencies in the surface and obtain a more even texture with coarser grain.

4. The tops were then machined and leveled in order to achieve the narrow tapering edge and then buffed and scrubbed with an oxidizing agent to obtain the pattinated finish.

2. The form-work was then used to create multiple moulds for sand-casting and parts that were to be duplicated.

3. The casts were then shot blasted to eliminate the inconsistencies in the surface and obtain a more even texture with coarser grain.

4. The tops were then machined and leveled in order to achieve the narrow tapering edge and then buffed and scrubbed with an oxidizing agent to obtain the pattinated finish.